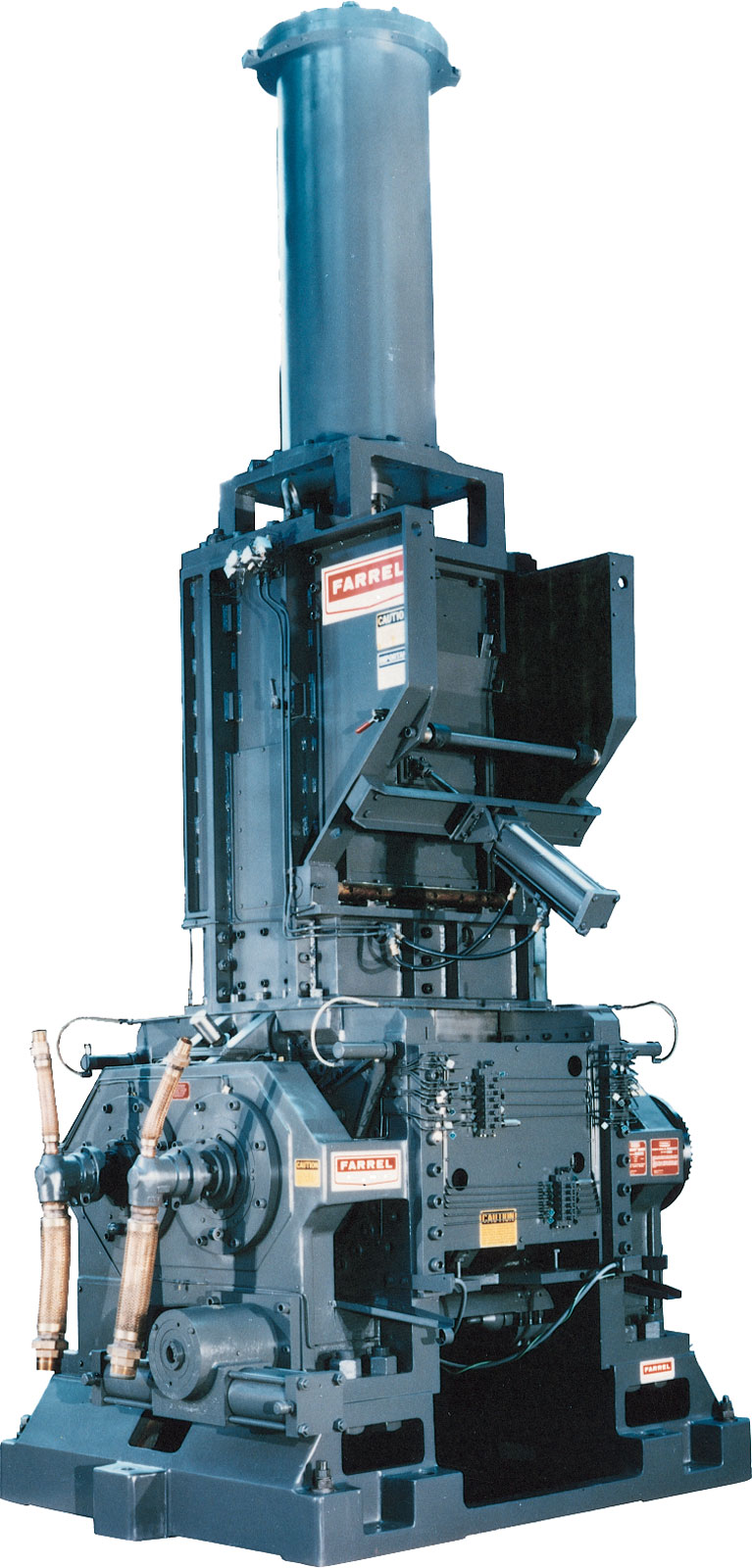

Flooring company Interfloor Ltd utilise Ralspeed’s Torqmaster soft starters on some of their Banbury mixers (between 350-450kw) alongside various blowers and blenders. An established client of over 12-years, Ralspeed were contacted to find a solution for a failed inverter on another 350kw mixer.

Following inspection, the inverter was deemed uneconomical to repair and a speedy solution was required. A full order book meant that downtime had to be kept to a minimum so as not to impact delivery times for their customers.

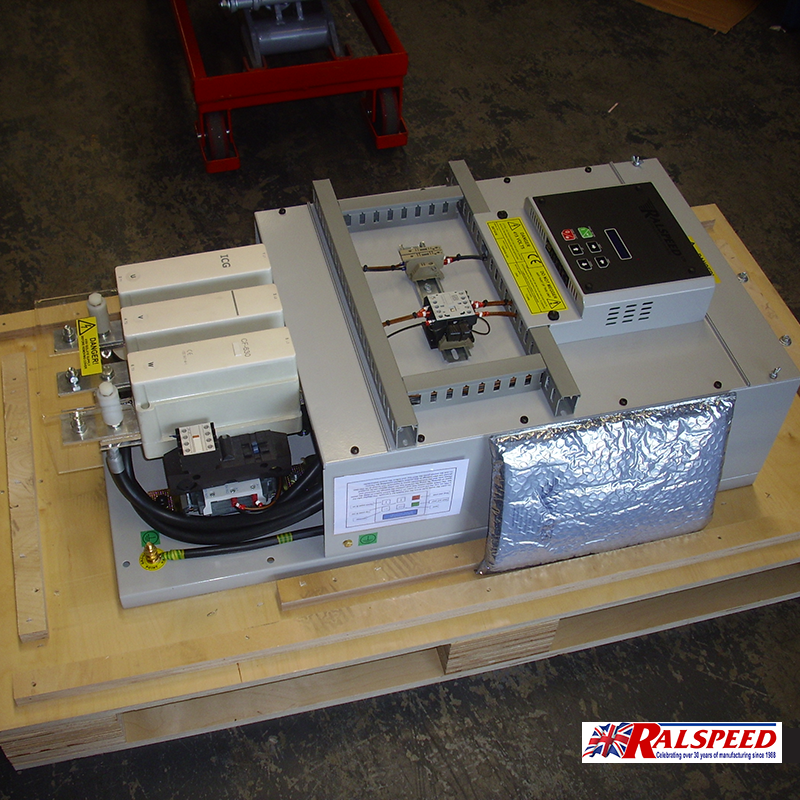

A full proposal was provided to Interfloor, which included the review of the use of a variable speed drive which was operating solely at full speed (50Hz). The drive was having serious overheating issues (due to the panel location) as well as wasting energy (money) as heat losses. It was agreed the variable speed drive was not required for this application and the Ralspeed team moved forward with the manufacture and installation of the Torqmaster soft start in a four-day timescale.

Not only was downtime kept to a bare minimum, the new soft start was integrated smoothly into the existing control panel and resolved the cooling issues Interfloor were experiencing with the previous variable speed drive. The thyristors on the soft start are taken out of circuit (bypassed) when the machine is up to full speed, eliminating most of the heat generated during operation.

The Torqmaster has proved an extremely reliable product and when Interfloor commissioned a new production line, they specified Ralspeed’s Torqmaster due to the previous track record of both performance of the starter and service back-up provided by the Ralspeed team.