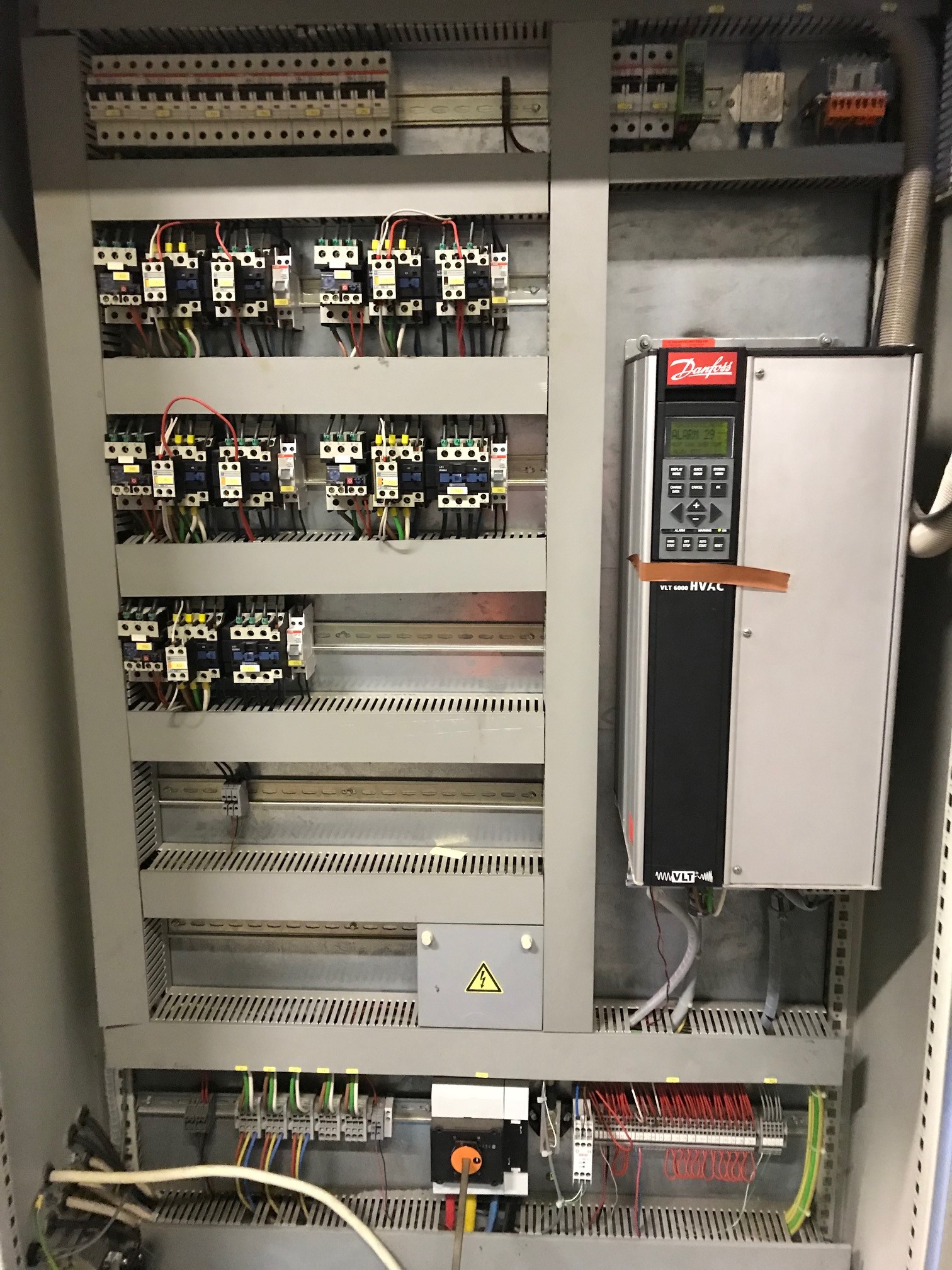

Tulip, one of the UK’s leading food producing companies, required a replacement for both a VLT6000 legacy drive which was unserviceable, in addition to an external temperature/multi pump controller that was also obsolete. Tulip were operating the production line part-manually to overcompensate for the outdated controller which was creating inefficiencies in the process and was ultimately costing money.

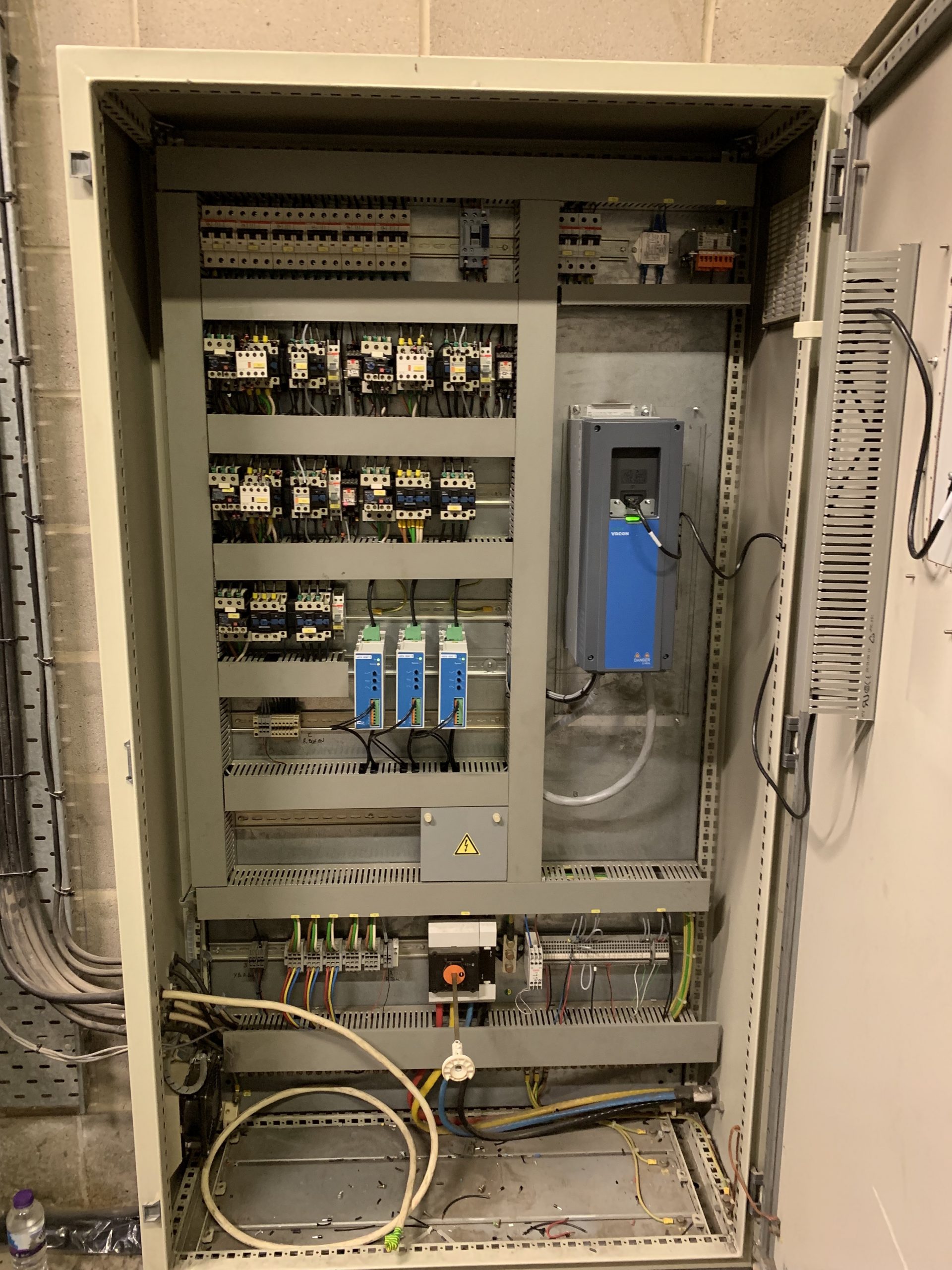

Following an on-site audit by the Ralspeed technical team, the legacy drive was replaced with a Danfoss Vacon 100 Flow drive. This specific drive was ideal with its built multi-pump application, as it removes the need for any external controllers. The previous set up was controlling the four pumps (each 11Kw) through a series of DOL contactors and the VLT6000.

Replacing with the Vacon 100 Flow drive and installing small soft starts, this allowed complete flexibility over process control and increased system efficiency. The in-built application means only the specific number of pumps need to run at any one time, with speed control right across the process range. Another benefit was duty rotation of lead pumps, giving a reduction of mechanical wear and tear.